Recent Projects

Gauge Design

A gauge is used to measure a specification. We can design a wide range of gauges — from a sophisticated digital gauge that can send readouts to a computer to a simple "go-no go" gauge. We also can certify and recertify.

See More Photos of Fixtures and Gauges

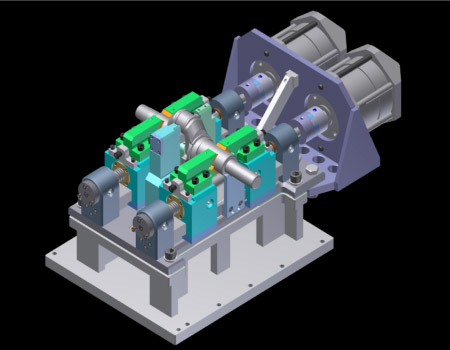

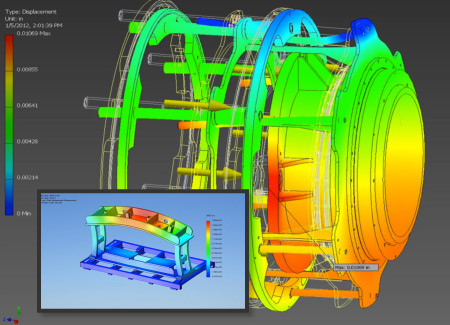

Fixture Design

This fixture replaced an existing fixture that was producing parts that were starting to deviate from the customer's requirements. B&B studied the existing fixture and process. Our team developed a new concept to address the issues of part movement during the machining process while maintaining ergonomics, cycle time, space constraints, existing controls, machine base, spindles and end tooling.

The site study determined that the existing fixture was not locating the part accurately and the sequence of operation and part retention methods were further compounding this issue. The new fixture accurately positions the part in its original location utilizing a number of custom made pneumatically operated actuators that position the part according to datum locations. The actuators are sequenced so as to locate the critical datums first. After part position is achieved, then two hydraulically driven ACME screws drive the clamps into the product. The clamp face is designed to hold the product in position while the machining operation is accomplished. The new fixture was then accurately installed on the existing machine base. After completion of a successful run off, the documentation package, including assembly drawings, pneumatic and hydraulic schematics, and detail drawings, was provided in the customer's requested format.

Large Machine Project

This project used the Kuraki Horizontal Boring Mill. More information on this project coming soon.

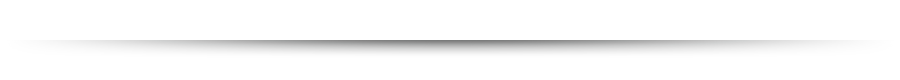

Material Stress Analysis

When we use analysis in conjunction with 3D virtual prototyping, we can test a range of structural and thermal properties. Costly and laborious physical prototyping can hinder a design team, resulting in compromised schedules and budgets. We can run computer simulations to help the design engineer better understand product performance and accommodate the changes needed prior to cutting the first chip. This process can also be used to help identify the reason for premature part failure and to test possible solutions. CEA (Cost Effective Analysis) types include linear static, modal, buckling, contact and steady state thermal.

Contact B&B Machine at 615-643-3354.

Machine Controls

We can build to your specifications and needs or provide recommendations and turn key solutions. We have experience with electrical/hydraulic/pneumatic logic circuits and controls. Our team is able to combine the different control systems and tailor a solution that will meet your unique requirements.

Contact B&B Machine at 615-643-3354 for more information or to get a quote on your project.

Manufactured Parts

Here is sampling of some of the parts designed and manufactured by B&B Machine. We can manufacture the very small and very large without sacrificing quality. All parts regardless of size are precisely machined to meet or exceed the required tolerances.